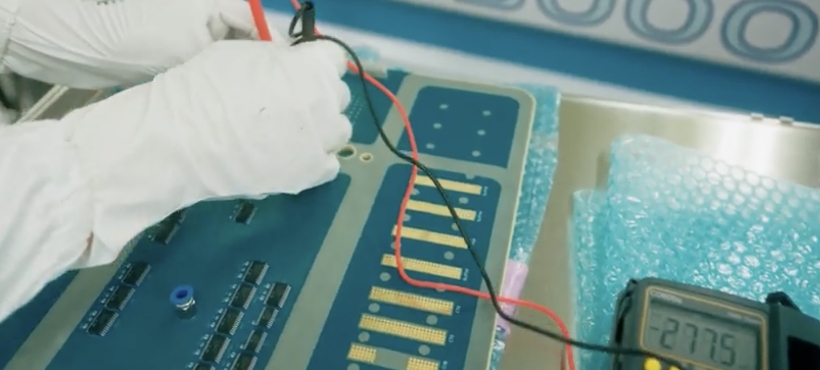

Test Operation

Service

We provide wafer test and final test services for a wide variety of semiconductor products which demand has been increasing.

We provide our customers with security and reliability setting up the optimal test environment, such as one of the best dedicated clean room in Japan, and with have an improved efficiency of mass production with support of the skilled engineers.

Our Services

-

Operation

24 hours a day, We utilize testers*1 and probers*2 to electrically test to verify whether or not the semiconductor products meet customer’s specifications.

We will provide a wide range of support such as suitable allocation for customers, improvement of testing efficiency, and root cause analysis.Our main testing

Verification of function with electric signals; stress test with high temperature/bias to remove early failed products before shipment; and, Visual inspection

-

Our technology supporting operations

Repair and inspection of equipment such as testers*1, probers*2, and probe cards*3 used for testing require know-how: e.g. maintenance of probe card needs advanced skill to fix a needle with a size of one-hundreds of 1mmwith tweezers to return it to the right place. Also, testing with high temperature/bias requires technical qualifications and expertise.

-

*1 Tester:

An equipment for testing electrical properties of semiconductors

-

*2 Prober:

An equipment to which a probe card is attached used in connection with a tester

-

*3Probe card:

A connecting jig (probe) used for electrical test of semiconductor chips for in wafer testing. It connects a pad (electrodes) of a semiconductor chip and a tester. A semiconductor chip is electrically tested and verified for pass/fail judgments by connecting probe to pad. Since a probe layout changes depending on a pad position of a semiconductor chip, a dedicated probe card is required for each product.

The technologies supporting operations and

a lot of accumulated data lead

to our various solutionsfor testing.

Tester Lineup

-

Logic (CPU, SoC)

- Services from wafer test to final test

- Support for products from small pins to multi-pin products

-

Image sensor (CIS, CCD)

- Compatible with high-speed CIS/CCD

- Alliance member of MIPI

- Test environment with dedicated clean room

- Experienced engineering support

-

Analog /Mixed Signal

- Reduction of test costs with the latest test equipment

- A wide range of test environments (from LSI linear ICs and power supply control ICs to RFLSIs)

-

Memory (DRAM, Flash)

- Technical capability based on a lot of experience in memory test

- On-site probe card maintenance support

We provide testing for a wide variety of semiconductor products with our tester lineup.

Click here for our tester lineup Click here for further inquiries| Classification. | Manufacturer | Type name | |

|---|---|---|---|

| Tester | SoC,MUC | ADVANTEST | T3347A |

| T6563 | |||

| T6575 | |||

| T6577 | |||

| T6573 | |||

| T6672 | |||

| T6673 | |||

| T2000LS | |||

| T2000EPP | |||

| V93000(PS1600) | |||

| Teradyne | J750EX | ||

| Megnum2 SV | |||

| Memory | ADVANTEST | T5335P | |

| T5371 | |||

| T5377 | |||

| T5377S | |||

| T5383 | |||

| T5722 | |||

| T5588 | |||

| T5593 | |||

| T5830 | |||

| T5833 | |||

| Analog/Mixed Signal | ADVANTEST | T2000IPS | |

| T7721 | |||

| EVA100 | |||

| Teradyne | μFlex | ||

| ETS-800 | |||

| ADVANTEST | V93000RF | ||

| Shibasoku | WL25 | ||

| WL25V | |||

| Sensor | Teradyne | IP70EP | |

| IP70EMP | |||

| IP750EX | |||

| ADVANTEST | IP750EX-HD | ||

| T2000ISS | |||

| Trimmer | ESI Group | model 9830 | |

| model 9850TP | |||

| M550 | |||

Other Services

Test Development Service